LightWELD®

Important Safety Information

The LightWELD system produces invisible laser light that may cause injuries to the operator

or individuals nearby during operation, maintenance or service. To ensure the safe operation

and optimal performance of the LightWELD product, follow all safety instructions and

warnings in the User Guide. Safe operation also requires adherence to all laser and welding

safety guidelines issued by the American National Safety Institute, including ANSI Z136.1

and ANSI Z49.1.

Safety precautions must be taken during all phases of operation, maintenance, and service.

For safety's sake, please ensure that all users review the User Guide in its entirety and are fully trained.

Safety precautions must be taken during all phases of operation, maintenance, and service.

For safety's sake, please ensure that all users review the User Guide in its entirety and are fully trained.

Laser Radiation

Exposure to laser light can inflict severe retina and/or cornea injuries

leading to permanent eye damage and may cause skin damage. Laser light may be

invisible. Safety protocols must be followed to prevent accidental exposure to

invisible, direct and reflected beams. The system must only be operated in a Laser

Controlled Area.* Skin Hazard Exposure to infrared (IR) and UV light radiation can cause

serious injury to the skin. Operators and all personnel working within the Laser

Controlled Area must wear protective clothing including laser-resistant and heat

resistant gloves, caps, leather apron and other laser-resistant and heat-resistant

clothing. Sleeves and collars should be buttoned at all times. Depending on the

intensity of the IR light, skin injuries may also include thermal burns or excessive dry

skin. Exposure to UV light may cause sunburn and will increase a welder's risk of skin

cancer and accelerated signs of skin aging. Welding sparks may also cause burns. Laser

beam can penetrate through metal parts to objects or persons on the other side. Never

hold parts for processing in a position where laser penetration of the metal may result

in a hazard.

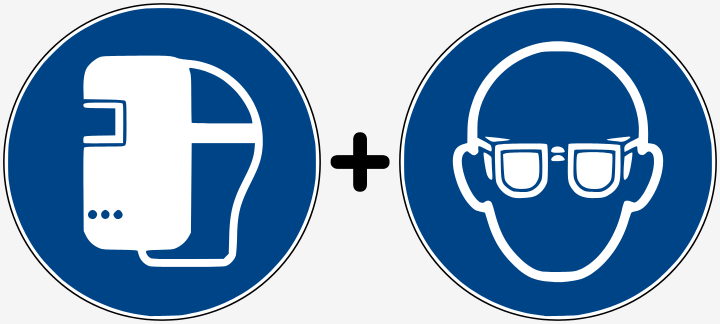

Eye Damage

All persons in the Laser Controlled Area must wear all recommended personal

protective equipment (PPE), including the provided IPG laser safety glasses and IPG

helmet with shield, provided with the LightWELD device, to protect against eye damage

from any reflected or scattered laser beams as well as welding bright light, ultraviolet

(UV) light, heat, and sparks. Only the combination of IPG laser safety glasses and

IPG helmet with face shield will provide sufficient protection to all personnel

present during laser welding. For safety reasons, do not use any laser safety

glasses or welding helmets other than those provided by IPG when the LightWELD device is

in use.

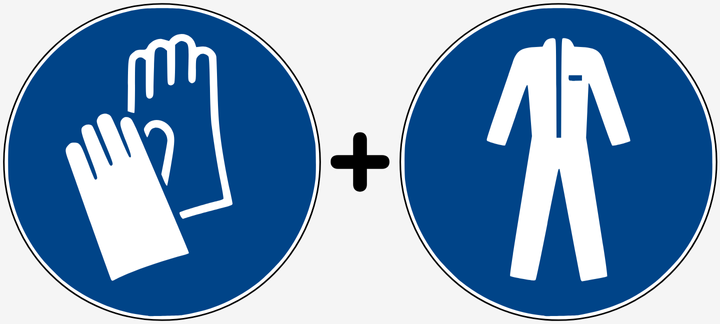

Skin Hazard

Exposure to infrared (IR) and UV light radiation can cause serious injury

to the skin. Operators and all personnel working within the Laser Controlled Area must

wear protective clothing including laser-resistant and heat resistant gloves, caps,

leather apron and other laser-resistant and heat-resistant clothing. Sleeves and collars

should be buttoned at all times.

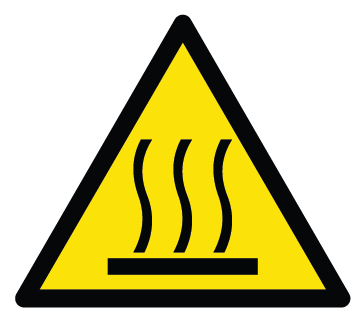

Depending on the intensity of the IR light, skin injuries may also include thermal burns

or excessive dry skin. Exposure to UV light may cause sunburn and will increase a

welder's risk of skin cancer and accelerated signs of skin aging. Welding sparks may

also cause burns. Laser beam can penetrate through metal parts to objects or persons

on the other side. Never hold parts for processing in a position where laser

penetration of the metal may result in a hazard.

Reflected Beam Hazard

Highly reflective metals such as aluminum and copper may cause reflection

of the laser energy away from the target weld site to the laser source or surrounding

area and may present a hazard to all individuals in the Laser Controlled Area. All

individuals in the Laser Controlled Area must wear all recommended PPE, including IPG

laser safety glasses and IPG welding helmet with face shield. Spectators should never

attempt to view the welding process or processed part from the opposite side of the

LightWELD device laser source. Spectators should only attempt to view the welding

process or processed parts from behind the operator of the LightWELD device, and only

when wearing all recommended PPE.

Fume Hazards

Welding "smoke" from interaction of the laser beam with target materials

can be comprised of very fine particles which can damage the lungs, heart, kidneys, and

central nervous system. During welding, aways keep your head away from fumes. Always

weld in an area with adequate ventilation and use a fume extraction system to remove

vapors, particles, and hazardous debris from the welding processing area.

Other Hazards

Welding heat and sparks can start a fire or cause an explosion in

combustible or flammable materials in the welding area. Laser welding should only be

performed in an area free of combustible or flammable materials. Never weld on

containers that have flammable or combustible material. If the contents of a container

are unknown, you should assume that they are flammable or combustible.

Gas cylinders must be stored only in areas where they cannot be struck by welding beams,

sparks or laser beam deflections. Working regulators suitable for proper storage and

pressure regulation of any gases are required. All hoses and fittings must also be

suitable for the gas types and pressures used in the welding application.

*As defined by ANSI, a Laser Controlled Area is "a laser use area where the

occupancy and activity of those within is controlled and supervised. This area may be

defined by walls, barriers or other means. Within this area, potentially hazardous beam

exposure is possible." Laser controlled areas are generally enclosed areas capable of

absorbing stray laser energy and equipped with a safety interlock to the laser to

prevent unauthorized access while laser is in use.